Add Your Heading Text Here

Add Your Heading Text Here

EXPERIENCE

Add Your Heading Text Here

SKILLS

Our Personnel are Qualified:

- API 510

- API 570

- API 653

- ASNT & PCN level 2 & 3

- IRATA Levels 2 &3

OUR OFFER

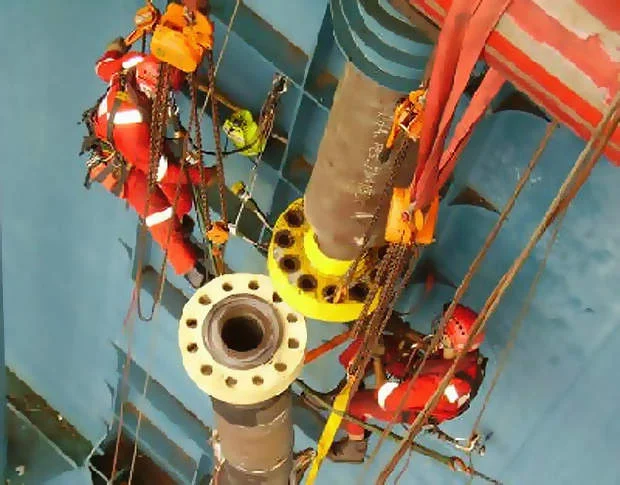

Whether topside, subsea or even in the splash zone, Odera Axiom offers an expansive collection of non-destructive testing (NDT) tools and robotic solutions that save time, money and most importantly, human risk factors in the volatile offshore atmosphere. Odera Axiom delivers innovative, consistent and reliable leading- edge technologies and services for:

|

- Plant Life Assessment

- Engineering Critical Assessments

- Maintenance Services – Asset Management

- Fitness for Service

- Inspection Engineering

- Support Services – Process Management

- Statutory

- Radiation Protection

Services

Services - Training and

- Vendor Inspection, Expediting and

- Quality Control

- Corrosion

- Rig

- Subsea Inspection, Repair &

- Pipeline

- Commissioning of FPSO &

- Asset Integrity Management Consultancy

- Laser Scanning and 3D modeling

EXPERIENCE

| Challenges | Our Solution |

| Internal Corrosion of Vessel Shell | Automated Phased Array Corrosion Mapping |

| Internal Corrosion of Dished Ends | Semi-Automated Phased Array Corrosion Mapping |

| Root Erosion/Corrosion of Circumferential and Seam Welds | Time of Flight Diffraction (TOFD) |

| Flange Face, Erosion of Nozzle Welds and Nozzle Bores Corrosion | Flange Face Phased Array and Manual Phased Array Corrosion Mapping |

| Corrosion Under Insulation -CUI | Pulsed Eddy Current and Computed |

| Radiography/Digital Radiography | |

| Corrosion Under Pipe Supports, Corrosion Under Saddle Supports , Corrosion Under Nozzle Compads/Lifting Lug attachments | Quantitative Short Range.. QSR |

| Pitting/Corrosion of Pipe Work | Various Automated & Semi-Automated Phased Array Corrosion Mapping techniques, and Digital Radiography |

| Erosion/Corrosion of Pipe Welds | TOFD/Small Bore Phased Array |

| Subsea and top side Fatigue cracking in jacket structures, pipeline weld integrity | Alternating Current Field Measurement -ACFM |

| Surface-forming scabs and corrosion blisters on offshore assets | Pulsed Eddy Current – PEC |

| Pipeline, Offshore piles and topside jetty lines inspections for metal loss features such as corrosion or erosion. | Long Range Ultrasonic Testing (LRUT) |

| The inspection of heat exchangers encompasses the assessment of the tubes found in a variety of assets including shell – and – tube heat exchangers, steam generators, boilers, coolers, feedwater heaters, and condensers. | IRIS System for ECT, RFT, NFT, MFL. The Eddyfi Ectane configurable for any type of inspection technique. |

| Tanks floors common failure mechanism is leakage through the floor, damaging the tank foundation which leads to instability possibly resulting in catastrophic failure | Magnetic Flux leakage – MFL |

| Leaks in pipelines (even if buried) and high-tension lines. | A thermal-imaging Matic- Drone inspection |

CHALLENGES OUR SOLUTION

Internal Corrosion of Vessel Shell – Automated Phased Array Corrosion Mapping

Internal Corrosion of Dished Ends – Semi-Automated Phased Array Corrosion Mapping

Root Erosion/Corrosion of Circumferential and Seam Welds – Time of Flight Diffraction (TOFD)

Flange Face, Erosion of Nozzle Welds and Nozzle Bores Corrosion – Flange Face Phased Array and Manual Phased Array Corrosion Mapping

Corrosion Under Insulation -CUI Pulsed Eddy Current and Computed – Radiography/Digital Radiography

Corrosion Under Pipe Supports, Corrosion Under Saddle Supports , Corrosion Under Nozzle Compads/Lifting Lug attachments – Quantitative Short Range.. QSR

Pitting/Corrosion of Pipe Work – Various Automated & Semi-Automated Phased Array Corrosion Mapping techniques, and Digital Radiography

Erosion/Corrosion of Pipe Welds – TOFD/Small Bore Phased Array

Subsea and top side Fatigue cracking in jacket structures, pipeline weld integrity – Alternating Current Field Measurement -ACFM

Surface-forming scabs and corrosion blisters on offshore assets – Pulsed Eddy Current – PEC

Pipeline, Offshore piles and topside jetty lines inspections for metal loss features such as corrosion or erosion – Long Range Ultrasonic Testing (LRUT)

The inspection of heat exchangers encompasses the assessment of the tubes found in a variety of assets including shell – and – tube heat exchangers, steam generators, boilers, coolers, feedwater heaters, and condensers – IRIS System for ECT, RFT, NFT, MFL. The Eddyfi Ectane configurable for any type of inspection technique.

Tanks floors common failure mechanism is leakage through the floor, damaging the tank foundation which leads to instability possibly resulting in catastrophic failure – Magnetic Flux leakage – MFL

Leaks in pipelines (even if buried) and high-tension lines – A thermal-imaging Matic- Drone inspection

Add Your Heading Text Here

PROJECTS

Add Your Heading Text Here